Product Description

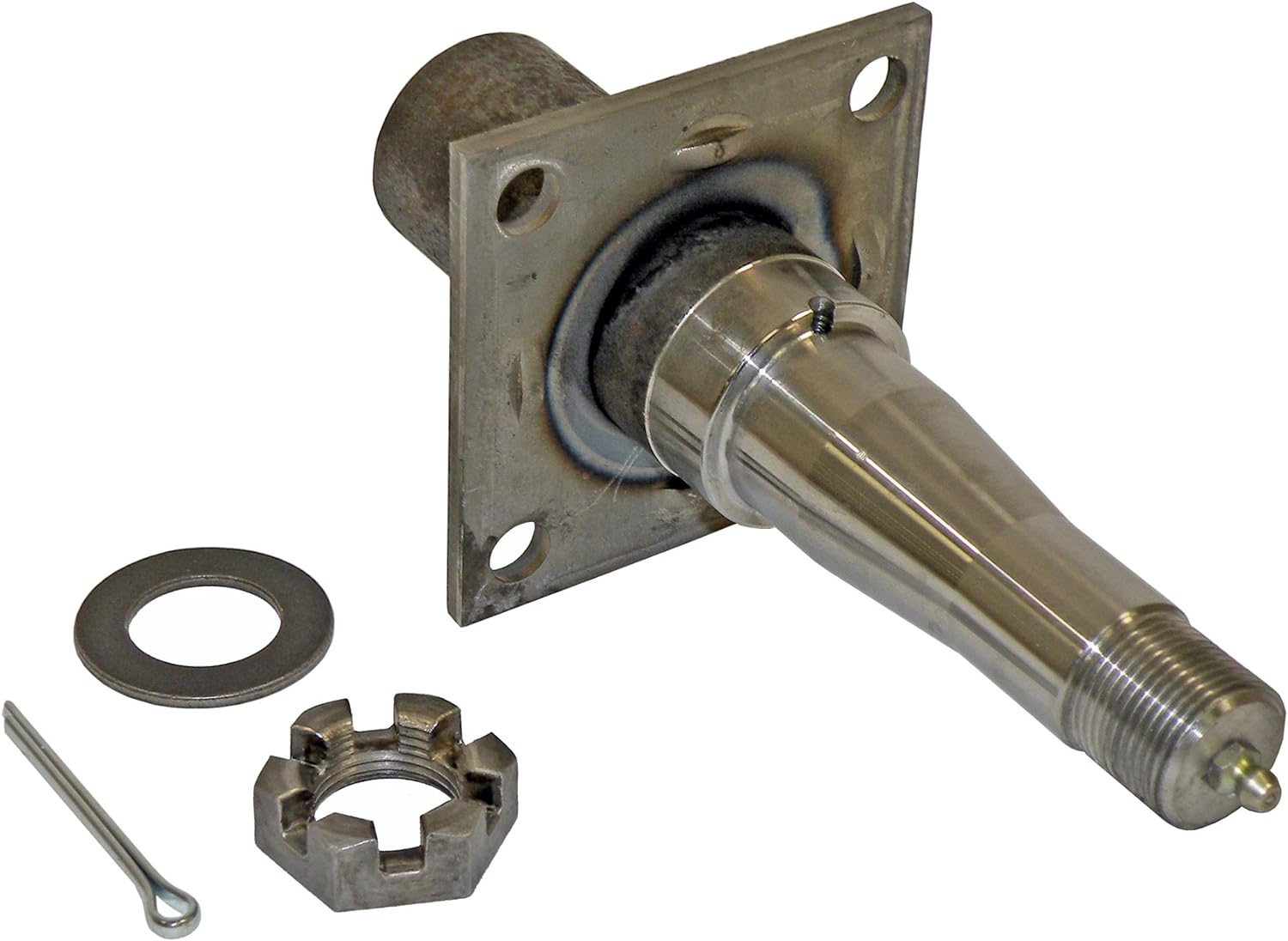

Factory Wholesale 50mm Trailer Solid Steel Round Stub Axle Spindle

A wide range of sizes with quality stub axles available. Axles are very easy to replace. Sturdy steel construction to ensure durability.

| Part Number | Description | Capacity | Brake Flange | Bearings ID | Bearings no. | Stub Length | Grease Seal ID | Nuts Size |

| S1008 | Round Spindle Dia.1.25″,BT8 | 1000 lbs | W/O | 1″x1″ | L44643 x2 | Customized | 1.24″ | 1″-14 UNF |

| S1016 | Round Spindle Dia.1.25″,BT16 | 1000 lbs | W/O | 1.06″x1.06″ | L44649 x2 | Customized | 1.24″ | 1″-14 UNF |

| S125016 | Round Spindle Dia.1.57″,BT16 | 1250 lbs | W/O | 1.06″x1.06″ | L44649 x2 | Customized | 1.5″ | 1″-14 UNF |

| S175084 | Round Spindle Dia.1.75″,#84 | 1750 lbs | W/O | 1.38″x1.06″ | L68149 x L44649 | Customized | 1.73″ | 1″-14 UNF |

| S3042 | Round Spindle Dia.2.25″,#42 | 3000 lbs | W/O | 1.74″x1.25″ | 25580 x 15123 | Customized | 2.24″ | 1″-14 UNF |

| S175084F | Round Spindle Dia.1.75″,#84 | 1750 lbs | Yes | 1.38″x1.06″ | L68149 x L44649 | Customized | 1.73″ | 1″-14 UNF |

| S3042F | Round Spindle Dia.2.25″,#42 | 3000 lbs | Yes | 1.74″x1.25″ | 25580 x 15123 | Customized | 2.24″ | 1″-14 UNF |

| S750R39 | 39mm Round Stub Axle | 750 kg/pr | W/O | LM Bearings | LM67048 x LM11949 | Customized | 36.5mm | 3/4″-16 UNF |

| S10S40 | 40mm Square Stub Axle | 1000 kg/pr | W/O | LM Bearings | LM67048 x LM11949 | Customized | 36.5mm | 3/4″-16 UNF |

| S1250S45 | 45mm Square Stub Axle | 1250 kg/pr | W/O | SL Bearings | L68149 x LM12749 | Customized | 42mm | 3/4″-16 UNF |

| S1250R50 | 50mm Round Stub Axle | 1250 kg/pr | W/O | SL Bearings | L68149 x LM12749 | Customized | 42mm | 3/4″-16 UNF |

| S15S45 | 45mm Square Stub Axle | 1500 kg/pr | W/O | 1.5T Bearings | LM29749 x L44649 | Customized | 44.45mm | 1″-14 UNF |

| S15R50 | 50mm Round Stub Axle | 1500 kg/pr | W/O | 1.5T Bearings | LM29749 x L44649 | Customized | 44.45mm | 1″-14 UNF |

| S15S45P | 45mm Square Stub Axle Parallel | 1500 kg/pr | W/O | Parallel | L68149 x L68149 | Customized | 42mm | 1″-14 UNF |

| S20S50 | 50mm Square Stub Axle | 2000 kg/pr | W/O | 2.0T Bearings | 25580 x LM67048 | Customized | 55mm | 1″-14 UNF |

| S20R56 | 56mm Round Stub Axle | 2000 kg/pr | W/O | 2.0T Bearings | 25580 x LM67048 | Customized | 55mm | 1″-14 UNF |

| S30R63 | 63mm Round Stub Axle | 3000 kg/pr | W/O | 3.0T Bearings | 35710 x LM29749 | Customized | 61mm | 1″-14 UNF |

| S30S65 | 65mm Square Stub Axle | 3000 kg/pr | W/O | 3.0T Bearings | 35710 x LM29749 | Customized | 61mm | 1″-14 UNF |

1) Do you have factory?

CZPT :

Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

2) Do you provide sample? Free or charge?

CZPT :

Sample can be submitted for clients check and approval ; Normal sample will be take cost and can be consider to return back since order be placed.

3) What is your MOQ?

CZPT :

MOQ 1-200 for trailer spring

MOQ 3000 for trailer suspension parts assembly

4) Can you manufacture the parts according to our size?

CZPT :

Depend on make tooling we can support your to be achieved your fixed request size for items.

5) What is your term of payment?

CZPT :

Normally for bulk TT., Irrevocable L/C at sight will be workable.

For samples , Paypal can be accept.

6) How long is your delivery time?

CZPT :

Normal 25 working days for delivery ;

CZPT time be about 35 working days.

7) Can I delivery the goods from other supplier to your factory? Then load together?

CZPT :

Sure ,we can accept and support . /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year Under Regular Opertion |

| Type: | Axle |

| Certification: | ISO/TS16949, ISO |

| Loading Weight: | 2T |

| ABS: | Without ABS |

| Customization: |

Available

| Customized Request |

|---|

How do I properly inspect an axle spindle for signs of wear or damage?

Inspecting an axle spindle for signs of wear or damage is an important part of vehicle maintenance. Here is a detailed explanation of how to properly inspect an axle spindle:

Before starting the inspection, ensure the vehicle is safely supported on jack stands and the wheels are removed to provide clear access to the axle spindles. Here are the steps to follow:

- Visual Inspection: Begin by visually examining the axle spindle for any visible signs of wear, damage, or irregularities. Look for the following indications:

- Cracks or fractures on the spindle surface

- Bent or warped spindle

- Signs of excessive corrosion or rust

- Visible wear patterns or grooves

- Unusual discoloration or heat marks

- Tactile Inspection: Run your fingers along the surface of the spindle to feel for any roughness, pitting, or other abnormalities. Pay attention to any areas that feel excessively rough or have noticeable imperfections.

- Bearing Play: Check for excessive play or looseness in the wheel bearing by grasping the wheel at the top and bottom and attempting to move it back and forth. If there is noticeable play, it may indicate worn or damaged wheel bearings, which can affect the spindle’s performance.

- Runout Measurement: Using a dial indicator, measure the spindle’s runout. This involves checking for any deviation or wobbling of the spindle when it rotates. Attach the dial indicator to a fixed point on the suspension or brake assembly and position the indicator’s contact point against the spinning spindle. Slowly rotate the spindle and observe the dial indicator’s reading. Excessive runout can indicate a bent or warped spindle.

- Brake Component Alignment: Check the alignment of the brake components, including the brake rotor and caliper, in relation to the spindle. Ensure that the rotor sits flush against the spindle surface and that the caliper is properly aligned with the rotor. Misalignment can indicate a bent or damaged spindle.

- Seal and Bearing Inspection: If possible, remove the wheel bearing and seal to inspect them for any signs of damage, wear, or leakage. Look for pitting, excessive wear, or damaged seals. Replace the bearings and seals if necessary.

It’s important to note that axle spindle inspection may require specialized tools, such as a dial indicator or bearing puller. If you’re uncomfortable performing the inspection yourself or lack the necessary tools, it’s recommended to have a qualified mechanic or technician inspect the spindle for you.

Regular axle spindle inspections can help identify potential issues early on, allowing for timely repairs or replacements. If you notice any signs of wear, damage, or irregularities during the inspection, it’s advisable to consult a professional for further evaluation and necessary repairs.

In summary, properly inspecting an axle spindle involves a visual and tactile examination for signs of wear or damage, checking for bearing play, measuring runout, assessing brake component alignment, and inspecting the wheel bearings and seals. Follow the recommended steps and consider seeking professional assistance if needed.

Can a damaged axle spindle lead to safety concerns, and how urgent is the need for repair?

Yes, a damaged axle spindle can indeed lead to safety concerns, and the need for repair is typically urgent. The axle spindle is a critical component of a vehicle’s suspension system and is responsible for supporting the weight of the vehicle and transmitting driving forces to the wheels. Here’s why a damaged axle spindle poses safety risks and requires prompt repair:

- 1. Steering Control: An axle spindle connects to the steering components and wheel hubs. Damage to the spindle can result in reduced steering control, making it challenging to maneuver the vehicle safely, especially in emergency situations.

- 2. Wheel Stability: The spindle supports the vehicle’s wheels. If the spindle is damaged, it can lead to wheel instability, wobbling, or even detachment. This poses a severe risk of accidents, especially at higher speeds.

- 3. Braking Performance: A damaged spindle can affect the alignment and performance of the braking system. This may result in uneven braking, longer stopping distances, or a loss of braking effectiveness, compromising safety during braking maneuvers.

- 4. Suspension Integrity: The axle spindle is a key structural component of the suspension system. A damaged spindle can weaken the overall suspension integrity, potentially leading to loss of control, swaying, or erratic handling.

- 5. Risk of Collisions: A vehicle with a damaged axle spindle may become unpredictable and pose a risk of colliding with other vehicles, obstacles, or pedestrians due to compromised stability and handling.

- 6. Towing and Hauling Risks: For vehicles used for towing or hauling heavy loads, a damaged spindle can lead to catastrophic failures when subjected to increased stress. This can result in accidents or loss of cargo.

- 7. Uneven Tire Wear: Axle spindle damage can cause uneven tire wear, reducing the tires’ grip and compromising traction, especially in adverse road conditions.

Given the critical role of the axle spindle in vehicle safety, any signs of damage or wear should be taken seriously, and repairs should be prioritized. Immediate inspection by a qualified mechanic is essential if you suspect spindle damage. Delaying repairs can lead to worsened safety risks, increased repair costs, and potential accidents. Regular vehicle maintenance and inspection can help detect spindle issues early and prevent safety concerns.

What are the common signs of a worn or faulty axle spindle, and how can they be identified?

A worn or faulty axle spindle can exhibit several common signs that indicate potential issues. Here’s a detailed explanation:

Identifying a worn or faulty axle spindle requires careful observation of the vehicle’s behavior and performance. Here are some common signs that may indicate problems with the axle spindle:

- Uneven Tire Wear: Excessive or uneven tire wear is often a sign of a worn or faulty axle spindle. Inspect the tires regularly and look for patterns of wear, such as excessive wear on the edges, scalloping, cupping, or feathering. Uneven tire wear suggests that the spindle is not properly supporting the wheel assembly or that the alignment is compromised.

- Steering Instability: A worn or faulty axle spindle can cause steering instability. If you notice that the steering feels loose, imprecise, or requires constant correction while driving, it could be a sign of a problem with the spindle. Pay attention to any vibrations or shimmying sensations felt through the steering wheel, as these can also indicate issues with the axle spindle.

- Pulling or Drifting: If the vehicle consistently pulls to one side or drifts off-center, it may be due to a worn or faulty axle spindle. This misalignment can cause uneven tire wear and affect the vehicle’s stability and handling. Keep an eye on the vehicle’s tendency to deviate from a straight path while driving on a level road.

- Noise or Grinding: A worn or faulty axle spindle can produce unusual noises. Listen for any grinding, clicking, or humming sounds coming from the wheel area while driving, especially during turns. These noises may indicate worn or damaged bearings within the spindle assembly, which require immediate attention.

- Excessive Play or Movement: Check for excessive play or movement in the wheel assembly by firmly gripping the tire at the 12 o’clock and 6 o’clock positions and attempting to rock it back and forth. Excessive play or movement can suggest a worn or loose axle spindle, which can compromise the vehicle’s stability and handling.

If you observe any of these signs, it is recommended to have the axle spindle inspected by a qualified mechanic or technician who can assess the condition of the spindle and perform the necessary repairs or replacement.

In addition to visual inspection and observation of the mentioned signs, specialized diagnostic tools may be used to further evaluate the condition of the axle spindle. These tools can measure wheel alignment, detect excessive play or movement, and identify any abnormalities in the spindle assembly.

Regular maintenance and periodic inspections of the suspension system can help in identifying early signs of axle spindle wear or faults. It’s important to address any issues promptly to prevent further damage and ensure the optimal performance and safety of the vehicle.

In summary, common signs of a worn or faulty axle spindle include uneven tire wear, steering instability, pulling or drifting, unusual noises, and excessive play or movement in the wheel assembly. Careful observation, visual inspection, and professional evaluation can help identify these signs and determine the condition of the axle spindle.

editor by CX 2024-01-30