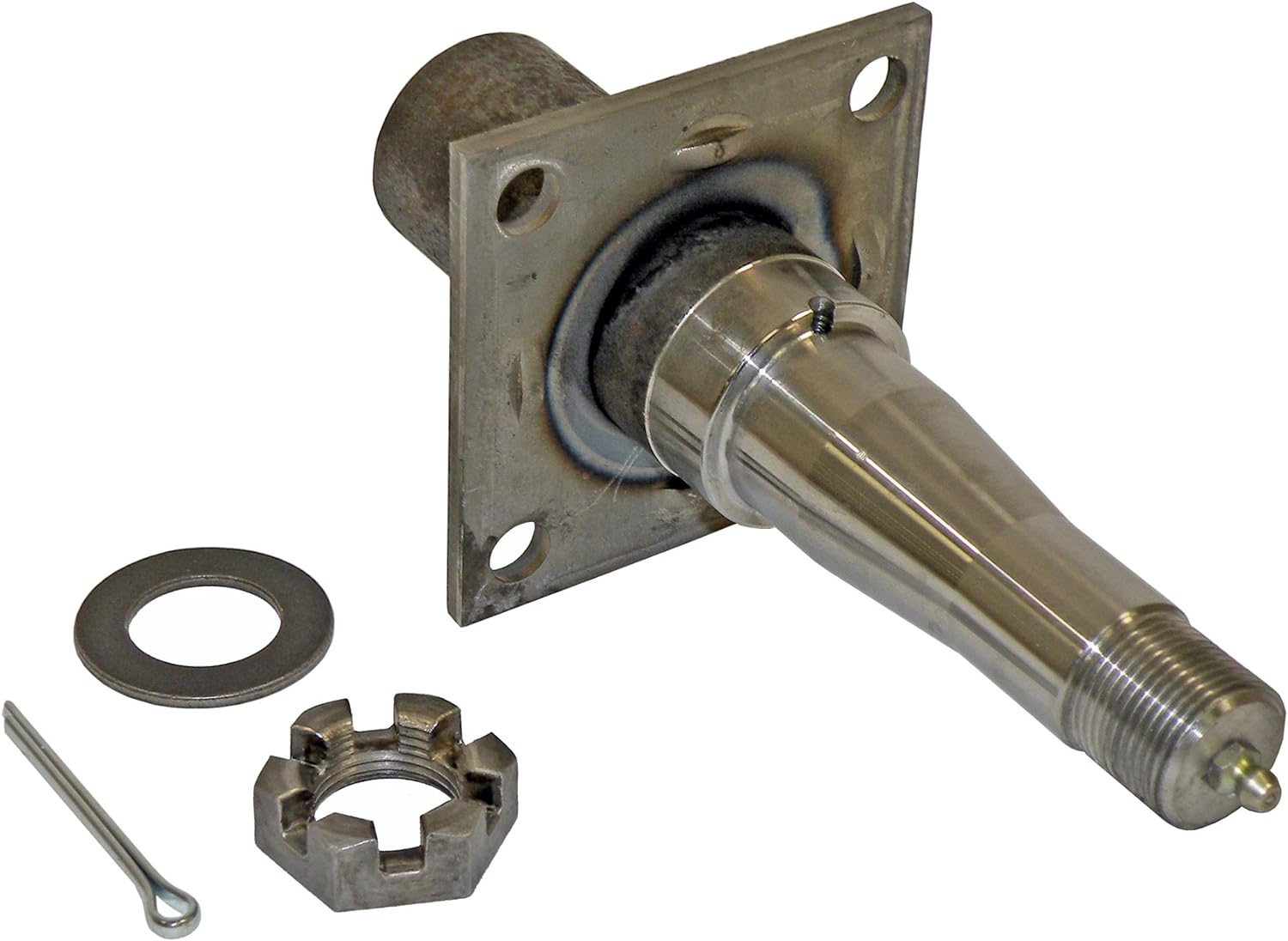

Product Description

Alloy Steel Trailer Axle Spindle

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to North America(10.00%),South America(10.00%),Southeast

Asia(10.00%),Africa(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Central America(10.00%),Northern Europe(10.00%),South

Asia(10.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

semi trailer axles, air suspensions , chamber,wheel ,slack adjuster and other related items.

4. why should you buy from us not from other suppliers?

We have a trailer parts production more than 10 years the supply chain

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.what is the certificate

At present, the company can undertake CCS, ABS, BV, GL and other certification products

| After-sales Service: | Availiable |

|---|---|

| Condition: | New |

| Axle Number: | 2 |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the torque specifications for securing an axle spindle to the suspension components?

The torque specifications for securing an axle spindle to the suspension components can vary depending on the specific vehicle make, model, and year. It’s important to refer to the manufacturer’s documentation or service manual for the accurate torque specifications. Here is a detailed explanation:

When installing or reassembling an axle spindle, it’s crucial to tighten the fasteners to the recommended torque specifications. This ensures proper clamping force and prevents issues such as overtightening, undertightening, or uneven loading. The torque specifications typically include values for the spindle nut, caliper bolts, and other related fasteners.

Since torque specifications can differ among vehicle models and years, it’s best to consult the appropriate manufacturer’s documentation or service manual for the exact torque values. These resources provide detailed information specific to your vehicle, ensuring accurate and safe installation. The documentation may be available in print form from the vehicle manufacturer, or in digital form through online service portals or third-party publications.

When referring to torque specifications, it’s essential to consider the following factors:

- Torque Units: Torque specifications are typically provided in either foot-pounds (ft-lbs) or Newton-meters (Nm). Ensure that you are using the correct unit of measurement to avoid errors.

- Torque Sequence: In some cases, the manufacturer may specify a specific sequence for tightening the fasteners. This sequence ensures even distribution of clamping force and proper alignment of components. Refer to the manufacturer’s documentation for any specified torque sequences.

- Thread Lubrication: Depending on the specific application, the manufacturer may recommend the use of a specific lubricant or thread-locking compound on the fasteners. Follow the manufacturer’s recommendations regarding lubrication to achieve accurate torque values.

- Re-Torqueing: In certain cases, the manufacturer may recommend re-torquing the fasteners after a specific mileage or driving time. This is done to account for any settling or relaxation that may occur in the components. Check the manufacturer’s documentation for any re-torqueing instructions.

It’s worth emphasizing that using the correct torque specifications is crucial to ensure the integrity and safety of the axle spindle and related components. Incorrectly tightened fasteners can lead to issues such as wheel bearing damage, premature wear, or even component failure.

If you are unsure about the torque specifications or lack the necessary tools and expertise, it is recommended to have a qualified mechanic or technician perform the installation or reassembly. They have the knowledge and experience to ensure that the axle spindle is secured with the appropriate torque, following the manufacturer’s specifications.

In summary, the torque specifications for securing an axle spindle to the suspension components vary depending on the vehicle make, model, and year. It is essential to consult the manufacturer’s documentation or service manual for the accurate torque values, taking into account torque units, torque sequence, thread lubrication, and any re-torqueing instructions. When in doubt, seek professional assistance to ensure proper installation and safe operation of the axle spindle.

How often should axle spindles be inspected as part of routine vehicle maintenance?

Inspecting axle spindles as part of routine vehicle maintenance is crucial for ensuring their continued performance, safety, and longevity. The frequency of axle spindle inspections can vary depending on several factors, including the vehicle type, driving conditions, and manufacturer recommendations. Here are some general guidelines:

- Manufacturer Recommendations: Refer to the vehicle’s owner’s manual or the manufacturer’s maintenance schedule for specific guidelines on axle spindle inspections. Manufacturers often provide recommended inspection intervals based on mileage or time, such as every 30,000 miles or every 2 years. Following the manufacturer’s recommendations ensures that you adhere to their specified maintenance intervals.

- Driving Conditions: Consider the driving conditions in which your vehicle operates. If you frequently drive in severe conditions such as off-road, dusty, or high-temperature environments, the axle spindles may require more frequent inspections. These conditions can contribute to accelerated wear or potential damage to the spindles, making more frequent inspections necessary to detect any issues early on.

- Visual Inspections: Perform visual inspections of the axle spindles regularly, especially during routine tire maintenance or brake inspections. Look for signs of damage, such as cracks, corrosion, or bent spindles. Pay attention to any unusual noise, vibration, or steering irregularities, as they can indicate potential issues with the spindles. If any abnormalities are observed, a more thorough inspection or professional evaluation should be conducted.

- Service Intervals: Take advantage of regular service intervals, such as oil changes or tire rotations, to have a qualified mechanic inspect the axle spindles. They can assess the condition of the spindles, check for proper lubrication, and identify any signs of wear or damage. The mechanic can recommend specific inspection intervals based on their expertise and the vehicle’s condition.

- Preventive Maintenance: In addition to regular inspections, consider incorporating preventive maintenance practices for your vehicle. This can include proactive measures such as applying protective coatings to the spindles, ensuring proper wheel alignment, and maintaining appropriate tire pressures. These actions can contribute to the longevity and optimal performance of the axle spindles.

It is important to note that the guidelines provided are general recommendations, and specific vehicle models or manufacturers may have different requirements. Therefore, always consult the vehicle’s owner’s manual or seek advice from a qualified mechanic or authorized dealership to determine the appropriate inspection frequency for the axle spindles in your vehicle.

Regular inspections of the axle spindles as part of routine vehicle maintenance help identify potential issues early, prevent further damage, and maintain the overall safety and reliability of the vehicle.

Can a failing axle spindle affect tire wear and alignment?

Yes, a failing axle spindle can indeed affect tire wear and alignment. Here’s a detailed explanation:

When an axle spindle is failing or damaged, it can have a direct impact on tire wear and alignment, leading to various issues. Here are some ways a failing axle spindle can affect tire wear and alignment:

- Uneven Tire Wear: A failing axle spindle can cause uneven tire wear patterns. The misalignment or instability resulting from a damaged spindle can lead to irregular contact between the tire and the road surface. This can cause specific areas of the tire to wear down more quickly than others. Common patterns of uneven tire wear include excessive wear on the edges or center of the tire, scalloping, cupping, or feathering. Uneven tire wear not only compromises tire lifespan but also affects vehicle handling and performance.

- Pulling or Drifting: A failing axle spindle can cause the vehicle to pull or drift to one side. This misalignment can be a result of the damaged spindle not allowing the wheels to be properly aligned. As a consequence, the tires on one side of the vehicle may experience increased friction and wear compared to the other side. This can lead to uneven tire wear and affect the vehicle’s stability and handling.

- Decreased Traction: A failing axle spindle can result in reduced traction between the tires and the road surface. Misalignment or instability caused by a damaged spindle can affect the tire’s ability to maintain optimal contact with the road. This can lead to decreased grip and traction, particularly during cornering or in wet or slippery conditions. Decreased traction not only affects tire wear but also compromises the vehicle’s overall safety and handling.

- Alignment Issues: A failing axle spindle can contribute to alignment problems. The damaged spindle may prevent the proper adjustment and alignment of the wheels. This can result in misaligned toe, camber, or caster angles, which directly impact tire wear. Improper alignment puts uneven stress on the tires, leading to accelerated wear and reduced tire lifespan.

- Compromised Steering Stability: A failing axle spindle can affect steering stability. Instability or misalignment caused by a damaged spindle can result in imprecise steering response and reduced control over the vehicle. This can lead to uneven tire loading and wear, as well as affect the overall handling and safety of the vehicle.

Addressing a failing axle spindle is crucial to prevent further damage to the tires and maintain proper alignment. If you notice uneven tire wear, pulling or drifting, decreased traction, or other signs of tire-related issues, it’s recommended to have the axle spindle inspected by a qualified mechanic or technician. They can accurately diagnose the problem and perform the necessary repairs or replacement to restore proper alignment and prevent further tire wear and damage.

In summary, a failing axle spindle can have a direct impact on tire wear and alignment. It can cause uneven tire wear, pulling or drifting, decreased traction, alignment issues, and compromised steering stability. Timely inspection and repair of the failing axle spindle are essential to ensure optimal tire performance, prolong tire lifespan, and maintain safe vehicle operation.

editor by CX 2023-11-17