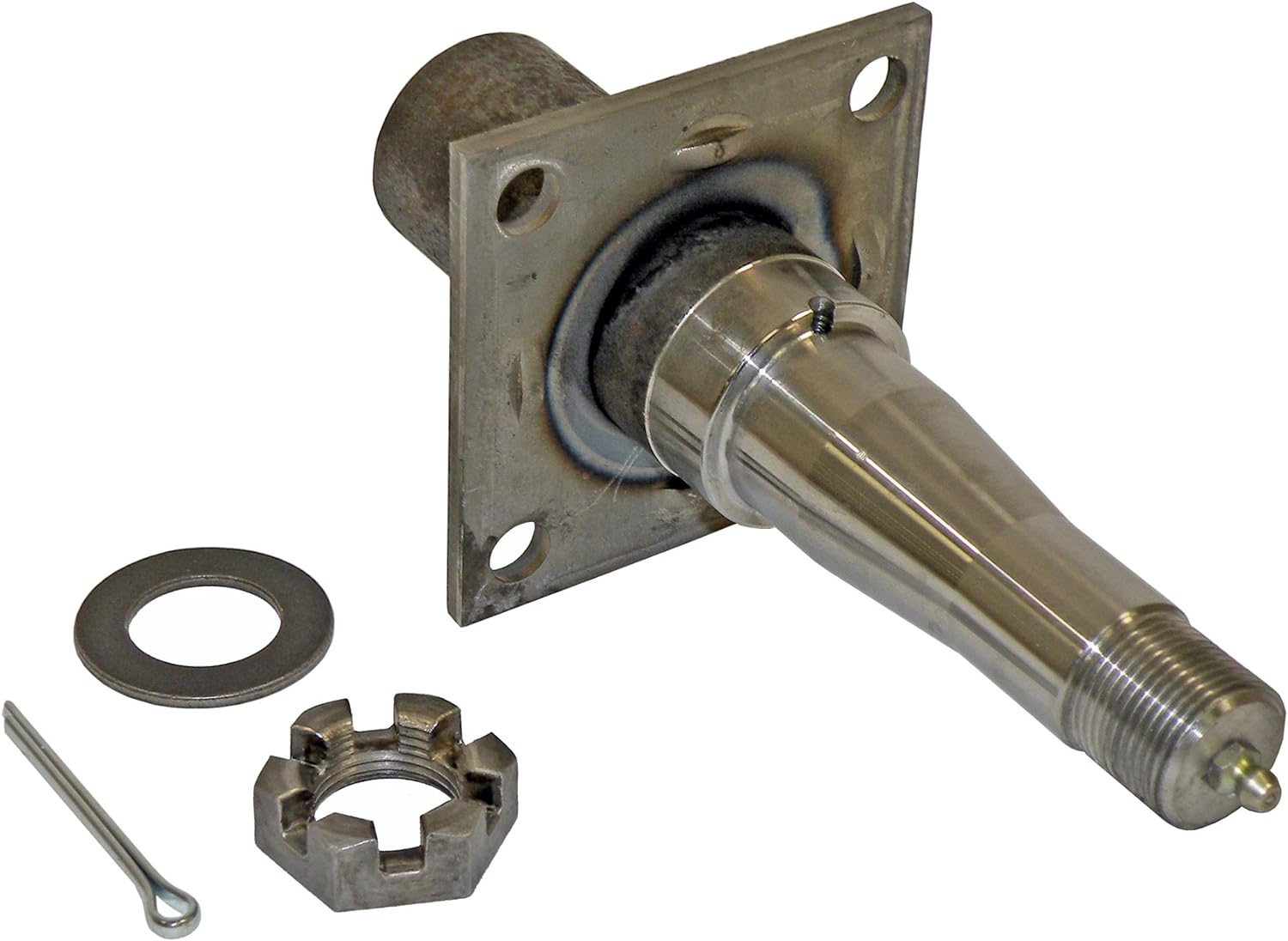

Product Description

| 1.name | Differential axle shaft |

| 2.OE NO.: | AB394B434AA AB39-4B434-AA EB3G3B079BF AB393B079AC EB3G-3B079-BF |

| 3.Car Make: |

for go kart CZPT Ranger |

| 4.Part Type: | Chassis system |

| 5.MOQ: | 50 PCS |

| 6. Price : | EXW Price |

| 7.Shipping Way: | By Sea, DHL, UPS, FEDEX or as customers’ requirements |

| 8.Payment Terms: | Via T/T ,L/C ,Paypal ,Westerm Union,Moneygram. |

| 9.Delivery Time: | Within 30 days after deposit or as customers’ requirement |

| 10.Packaging:Packaging: |

1.Carton Box, 4.We can perform according to customer’s requirements |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours |

|---|---|

| Warranty: | 1 Year |

| Type: | Other Engine Parts |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Where can I buy axle seals for preventing fluid leaks in my vehicle’s axles?

When it comes to purchasing axle seals to prevent fluid leaks in your vehicle’s axles, there are several options available. Here are some places where you can buy axle seals:

1. Automotive Parts Stores:

Visit local automotive parts stores such as AutoZone, Advance Auto Parts, O’Reilly Auto Parts, or NAPA Auto Parts. These stores typically have a wide range of automotive seals, including axle seals, in stock. You can either visit the physical store or check their online catalogs to find the specific axle seal you need for your vehicle.

2. Dealerships:

If you prefer to purchase genuine OEM (Original Equipment Manufacturer) axle seals, consider visiting a dealership authorized by your vehicle’s manufacturer. Dealerships often carry original parts that are specifically designed for your vehicle make and model. Contact your local dealership’s parts department to inquire about the availability of axle seals for your vehicle.

3. Online Retailers:

Online retailers like Amazon, eBay, and RockAuto offer a wide range of automotive parts, including axle seals. These platforms provide the convenience of browsing and purchasing axle seals from the comfort of your home. Make sure to check the product details, specifications, and customer reviews before making a purchase.

4. Local Mechanics and Repair Shops:

Local mechanics and repair shops often have access to a variety of automotive seals, including axle seals. They can source and install the appropriate seals for your vehicle during maintenance or repair services. Reach out to trusted local mechanics or repair shops in your area and inquire about their availability and pricing for axle seals.

5. Manufacturer’s Online Stores:

Some vehicle manufacturers have their own online stores where you can purchase genuine OEM parts, including axle seals. Visit the official website of your vehicle’s manufacturer and look for their online parts store. You can search for the specific axle seal needed for your vehicle using your vehicle identification number (VIN) or the model details.

6. Salvage Yards:

If you are looking for cost-effective options or rare axle seals, salvage yards can be an option. Salvage yards specialize in selling used parts salvaged from vehicles. However, when purchasing from salvage yards, it’s important to carefully inspect the condition and compatibility of the axle seals to ensure they are suitable for your vehicle.

When purchasing axle seals, make sure to provide accurate information about your vehicle’s make, model, and year to ensure you get the correct seals that fit your vehicle’s axle specifications. Additionally, consider factors such as the quality of the seals, warranty options, and return policies when making your purchase decision.

Remember, if you are unsure about the specific axle seals required for your vehicle or need assistance with installation, it is recommended to consult with a qualified mechanic or technician who can guide you in selecting the right seals and ensure proper installation to prevent fluid leaks in your vehicle’s axles.

What are the symptoms of a failing CV joint, and how does it relate to the axle?

A CV (constant velocity) joint is an essential component of the axle assembly in many vehicles. When a CV joint starts to fail, it can exhibit several symptoms that indicate potential problems. Here’s a detailed explanation of the symptoms of a failing CV joint and its relationship to the axle:

Symptoms of a Failing CV Joint:

1. Clicking or popping sounds: One of the most common signs of a failing CV joint is a clicking or popping sound when making turns. This noise usually occurs during tight turns and may indicate worn-out or damaged CV joint bearings.

2. Grease leakage: A failing CV joint may leak grease, which can be seen as dark-colored grease splattered around the CV joint or on the inside of the wheel. Grease leakage is typically caused by a cracked or damaged CV joint boot, which allows the lubricating grease to escape and contaminants to enter.

3. Excessive vibration: A worn-out CV joint can cause vibrations, especially during acceleration. The vibrations may be felt in the steering wheel, floorboards, or even the entire vehicle. These vibrations can become more noticeable as the CV joint deteriorates further.

4. Difficulty in turning: As the CV joint wears out, it may become difficult to turn the vehicle, especially at low speeds or when making sharp turns. This symptom is often accompanied by a clicking or popping sound.

5. Uneven tire wear: A failing CV joint can lead to uneven tire wear. If the CV joint is damaged or worn, it can cause the axle to wobble or vibrate, resulting in uneven tire tread wear. This can be observed by visually inspecting the tires and noticing uneven patterns of wear.

Relationship to the Axle:

The CV joint is an integral part of the axle assembly. It connects the transmission to the wheels and allows smooth power delivery to the wheels while accommodating the up-and-down motion of the suspension. The axle shaft is responsible for transmitting torque from the transmission to the CV joints and ultimately to the wheels.

Axles contain one or more CV joints, depending on the vehicle’s drivetrain configuration. In front-wheel drive vehicles, each front axle typically has two CV joints, one inner and one outer. Rear-wheel drive and all-wheel drive vehicles may have CV joints on both the front and rear axles.

The CV joint consists of a joint housing, bearings, and internal ball bearings or rollers. It is protected by a rubber or thermoplastic CV joint boot, which seals in the grease and protects the joint from contaminants. When the CV joint fails, it can affect the axle’s ability to transmit power smoothly and result in the symptoms mentioned above.

Regular inspection and maintenance of the CV joint and axle assembly are crucial to identify and address any issues promptly. If any of the symptoms mentioned earlier are observed, it is recommended to have the vehicle inspected by a qualified mechanic to determine the exact cause and perform necessary repairs or replacements.

What is the primary function of an axle in a vehicle or machinery?

An axle plays a vital role in both vehicles and machinery, providing essential functions for their operation. The primary function of an axle is to transmit rotational motion and torque from an engine or power source to the wheels or other rotating components. Here are the key functions of an axle:

- Power Transmission:

- Support and Load Bearing:

- Wheel and Component Alignment:

- Suspension and Absorption of Shocks:

- Steering Control:

- Braking:

An axle serves as a mechanical link between the engine or power source and the wheels or driven components. It transfers rotational motion and torque generated by the engine to the wheels, enabling the vehicle or machinery to move. As the engine rotates the axle, the rotational force is transmitted to the wheels, propelling the vehicle forward or driving the machinery’s various components.

An axle provides structural support and load-bearing capability, especially in vehicles. It bears the weight of the vehicle or machinery and distributes it evenly across the wheels or supporting components. This load-bearing function ensures stability, balance, and proper weight distribution, contributing to safe and efficient operation.

The axle helps maintain proper alignment of the wheels or rotating components. It ensures that the wheels are parallel to each other and perpendicular to the ground, promoting stability and optimal tire contact with the road surface. In machinery, the axle aligns and supports the rotating components, ensuring their correct positioning and enabling smooth and efficient operation.

In vehicles, particularly those with independent suspension systems, the axle plays a role in the suspension system’s operation. It may incorporate features such as differential gears, CV joints, or other mechanisms that allow the wheels to move independently while maintaining power transfer. The axle also contributes to absorbing shocks and vibrations caused by road irregularities, enhancing ride comfort and vehicle handling.

In some vehicles, such as trucks or buses, the front axle also serves as a steering axle. It connects to the steering mechanism, allowing the driver to control the direction of the vehicle. By turning the axle, the driver can steer the wheels, enabling precise maneuverability and navigation.

An axle often integrates braking components, such as brake discs, calipers, or drums. These braking mechanisms are actuated when the driver applies the brakes, creating friction against the rotating axle or wheels and causing deceleration or stopping of the vehicle. The axle’s design can affect braking performance, ensuring effective and reliable stopping power.

Overall, the primary function of an axle in both vehicles and machinery is to transmit rotational motion, torque, and power from the engine or power source to the wheels or rotating components. Additionally, it provides support, load-bearing capability, alignment, suspension, steering control, and braking functions, depending on the specific application and design requirements.

editor by CX 2024-04-04

China factory Factory Bicycle Rear Spindle Axle axle shaft

Product Description

Factory Bicycle Rear Spindle Axle

Product Description

| Product Information | ||

| Model: | TJ-HUB-002 | |

| Diameter: | a). 3/8″,5/16” | |

| Size: | 130-150mm | |

| Color: | a). UCP | b). ED |

| Material: | Steel | |

| Hub Cone: | a). Normal Cone | |

| Hub Lock Nut: | a). 3/8″,5/16” | |

| Nut: | a). Normal Nut | b). Flange Nut |

| Spacer: | Yes | |

| Total Pieces: | 7 Pieces or as order | |

| Brand Name: | TIXIHU (WEST LAKE) DIS.U or OEM | |

| Applicable Bicycle: | Road Bicycle, Traditional Bicycle,MTB | |

| Minimum Order Quantity: | 1000 Sets | |

| Place of Origin: | HangZhou, ZheJiang , China | |

| Shipping Port: | a). ZheJiang | |

| Packaging Details: | a). 200 pcs /Ctn | |

| Delivery Time: | a). 15days after receiving deposit | |

| Payment Terms: | a). T/T | b). L/C |

| Supply Ability: | 50,000 pieces per week | |

Packaging & Shipping

QTY: 200PCS

G.W: 29KGS

Sets: 13 PCS

MEAS: 32X23X25CM

Delivery Time: 15-30 days as order quantity

Company Profile

HangZhou Tianjiu Bicycle Parts Co. Ltd located in the biggest bicycle accessory base. We get a wonderful geography, convenient

traffic which near to the Jingzhu and Xihu (West Lake) Dis.g high speed way. And our company is closed to the famous China Bicycle

Accessory Town.

We are professional manufacturer in producing chain wheel&crank, saddle, inner tube, tyre, pedal, front axle, rear axle, MTB bicycle, BMX bicycle, child toys, etc. branded “TIXIHU (WEST LAKE) DIS.U”. Meanwhile, we have the autonomy in operation of the import and

export business. Our company has a dozen of great profession product machines. And our productions get a well sale to the bicycle factory and accessories manufactures production all over the country, which based on good quality, cheap price, and perfect after-sales service. So our export sales have been growing year by year. Our productions are spreading over 40 countries and regions including Southeast Asia, East Europe, Africa, and South America.

Hard work and CZPT pursuit is our spirit. Quality first and customer first is our principle. Everyone in TIXIHU (WEST LAKE) DIS.U Company is sincerely inviting the colleague all over the world to have cooperation and a better future.

Our Advantages

1. Manufacturer

2. Fashion design

3. Best service

4. Super quality

5. Reasonable price

6. Small MOQ

7. Well-deserved reputation

8. Fast delivery&convient transportation

9. Good after-sales service

FAQ

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Condition: | New |

| Certification: | CE, ISO9001 |

| Customized: | Non-Customized |

| Application: | Kids Bike, Road Bike, Mountain Bike, Ordinary Bicycle |

| Position: | Front/Rear |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the safety considerations when working with axles, especially during repairs?

Working with axles, especially during repairs, requires careful attention to safety to prevent accidents and injuries. Here are some important safety considerations to keep in mind when working with axles:

1. Personal Protective Equipment (PPE):

Wear appropriate personal protective equipment, including safety goggles, gloves, and steel-toed boots. PPE helps protect against potential hazards such as flying debris, sharp edges, and accidental contact with heavy components.

2. Vehicle Stability:

Ensure that the vehicle is on a stable and level surface before working on the axles. Engage the parking brake and use wheel chocks to prevent unintended vehicle movement. The stability of the vehicle is crucial to maintain a safe working environment.

3. Lifting and Support:

Use proper lifting equipment, such as hydraulic jacks or vehicle lifts, to raise the vehicle safely. Follow the manufacturer’s guidelines for lifting points and weight capacities. Once the vehicle is lifted, support it securely with jack stands or other appropriate supports to prevent it from falling or shifting during repairs.

4. Lockout/Tagout:

If the repair work involves disconnecting or removing any electrical or mechanical components that could cause the axle or wheels to move, follow lockout/tagout procedures. This involves locking and tagging out the power source, so it cannot be accidentally energized while work is being performed.

5. Proper Tools and Equipment:

Use the correct tools and equipment for the job. Using improper tools or makeshift methods can lead to accidents and damage to the axle or surrounding components. Follow the manufacturer’s instructions and recommended procedures for disassembling, repairing, and reassembling the axle.

6. Proper Torque and Tightening:

When reassembling the axle components, use a torque wrench to ensure that fasteners are tightened to the manufacturer’s specifications. Over-tightening or under-tightening can lead to component failure or damage. Follow the recommended torque values provided by the vehicle manufacturer.

7. Safe Handling of Heavy Components:

Axle components can be heavy and cumbersome. Use appropriate lifting techniques and equipment, such as hoists or lifting straps, to safely handle heavy axle parts. Avoid lifting heavy components alone whenever possible and ask for assistance when needed.

8. Proper Disposal of Fluids and Waste:

If the repair involves draining fluids from the axle, such as differential oil, ensure proper disposal according to local regulations. Use appropriate containers to collect and store fluids and dispose of them at authorized collection points.

9. Training and Experience:

Working with axles requires knowledge and experience. If you are unfamiliar with axle repairs, consider seeking assistance from a qualified mechanic or technician who has the necessary training and expertise. If you decide to perform the repairs yourself, ensure that you have the appropriate knowledge and skills to carry out the task safely.

By following these safety considerations, you can help minimize the risk of accidents, injuries, and damage when working with axles, ensuring a safe working environment for yourself and others involved in the repair process.

Are there specific maintenance tips to extend the lifespan of my vehicle’s axles?

Maintaining the axles of your vehicle is crucial for ensuring their longevity, performance, and overall safety. Here are some specific maintenance tips to extend the lifespan of your vehicle’s axles:

- Regular Inspection:

- Lubrication:

- Seal Inspection and Replacement:

- Proper Loading and Towing:

- Driving Techniques:

- Regular Wheel Alignment:

- Proper Tire Inflation:

- Service Intervals:

Perform regular visual inspections of the axles to check for any signs of damage, leaks, or excessive wear. Look for cracks, bends, or rust on the axle housing, and inspect the axle shafts, seals, and boots. Early detection of issues can help prevent further damage and costly repairs.

Follow the manufacturer’s recommendations for axle lubrication. Proper lubrication helps reduce friction and wear on the axle components. Regularly check the axle’s lubricant level and quality, and replace it as necessary. Use the recommended lubricant type and viscosity for your specific axle.

Check the axle seals for any signs of leaks, such as fluid accumulation around the axle ends. Leaking seals can allow contaminants to enter the axle assembly, leading to premature wear and damage. Replace worn or damaged seals promptly to maintain proper lubrication and prevent contamination.

Ensure that you do not exceed the weight capacity of your vehicle’s axles. Overloading or towing beyond the recommended limits can put excessive stress on the axles, leading to premature wear or failure. Be mindful of the payload and towing capacity specified by the vehicle manufacturer.

Adopt proper driving techniques to minimize stress on the axles. Avoid sudden acceleration, aggressive cornering, and harsh braking, as these actions can subject the axles to excessive forces. Additionally, be cautious when driving over rough terrain or obstacles to prevent impacts that could damage the axles.

Maintain proper wheel alignment to prevent excessive strain on the axles. Misaligned wheels can put uneven loads on the axles, leading to accelerated wear. Regularly check and adjust the wheel alignment as per the manufacturer’s recommendations.

Ensure that your vehicle’s tires are properly inflated according to the recommended tire pressure. Underinflated or overinflated tires can affect the load distribution on the axles and increase the risk of axle damage. Regularly check and maintain the correct tire pressure.

Follow the recommended service intervals for your vehicle, which may include axle inspections, lubricant changes, and other maintenance tasks. Adhering to these intervals ensures that the axles are properly maintained and any potential issues are addressed in a timely manner.

It’s important to consult your vehicle’s owner’s manual for specific maintenance guidelines and intervals provided by the manufacturer. Additionally, if you notice any unusual noises, vibrations, or handling issues related to the axles, it is advisable to have your vehicle inspected by a qualified mechanic to identify and address any potential axle problems promptly.

What is the primary function of an axle in a vehicle or machinery?

An axle plays a vital role in both vehicles and machinery, providing essential functions for their operation. The primary function of an axle is to transmit rotational motion and torque from an engine or power source to the wheels or other rotating components. Here are the key functions of an axle:

- Power Transmission:

- Support and Load Bearing:

- Wheel and Component Alignment:

- Suspension and Absorption of Shocks:

- Steering Control:

- Braking:

An axle serves as a mechanical link between the engine or power source and the wheels or driven components. It transfers rotational motion and torque generated by the engine to the wheels, enabling the vehicle or machinery to move. As the engine rotates the axle, the rotational force is transmitted to the wheels, propelling the vehicle forward or driving the machinery’s various components.

An axle provides structural support and load-bearing capability, especially in vehicles. It bears the weight of the vehicle or machinery and distributes it evenly across the wheels or supporting components. This load-bearing function ensures stability, balance, and proper weight distribution, contributing to safe and efficient operation.

The axle helps maintain proper alignment of the wheels or rotating components. It ensures that the wheels are parallel to each other and perpendicular to the ground, promoting stability and optimal tire contact with the road surface. In machinery, the axle aligns and supports the rotating components, ensuring their correct positioning and enabling smooth and efficient operation.

In vehicles, particularly those with independent suspension systems, the axle plays a role in the suspension system’s operation. It may incorporate features such as differential gears, CV joints, or other mechanisms that allow the wheels to move independently while maintaining power transfer. The axle also contributes to absorbing shocks and vibrations caused by road irregularities, enhancing ride comfort and vehicle handling.

In some vehicles, such as trucks or buses, the front axle also serves as a steering axle. It connects to the steering mechanism, allowing the driver to control the direction of the vehicle. By turning the axle, the driver can steer the wheels, enabling precise maneuverability and navigation.

An axle often integrates braking components, such as brake discs, calipers, or drums. These braking mechanisms are actuated when the driver applies the brakes, creating friction against the rotating axle or wheels and causing deceleration or stopping of the vehicle. The axle’s design can affect braking performance, ensuring effective and reliable stopping power.

Overall, the primary function of an axle in both vehicles and machinery is to transmit rotational motion, torque, and power from the engine or power source to the wheels or rotating components. Additionally, it provides support, load-bearing capability, alignment, suspension, steering control, and braking functions, depending on the specific application and design requirements.

editor by CX 2024-02-16

China Good quality Carbon Steel Shaft CNC Turning Spindle for Industrial Equipment Tool electric rear axle kit

Product Description

Carbon steel shaft cnc turning spindle for industrial equipment tool

Feature of CNC parts

1. Precision Cnc stainless steel parts strictly according to customer’s drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.Our freight price is often 30-50% lower than customer’s

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015 and ISO13485:2016

Material Available for CNC Machining

| Material | Stainless steel | SS201 SS303 SS304 SS316 17-4PH SUS440C |

| Steel | Q235 20#-45# etc | |

| Brass | C36000(C26800) C37700(HPb59) C38500(HP6 58) C27200(CuzN37)etc | |

| Iron | 1213 12L14 1215 etc | |

| Bronze | C51000 C52100 C5400etc | |

| Aluminum | Al6061 Al6063 Al7075 AL5052 etc | |

| Alloy | A2 D2 SKD11 DF2 XW/5 ASP-23 |

Terms and Conditons

| Our Processing | CNC machining, CNC milling and turning, drilling, grinding, , stamping, tapping, |

| Surface finish | Hard Coating Black Anodize Clear Anodize Hard Chrome ,Clear Zinc Plasma Niride |

| Tolerance | 0.005mm |

| QC System | 100% inspection before shipment |

| Drawing format | DWG/ IGS/ STEP/STEP,/IGES/X-T/PDF and etc. |

| Packaging | Standard package / Carton box or Pallet / As per customized specifications |

| Payment Terms | 1) Western Union for samples cost or very small order 2) 100% T/T in advance when amount less than 1000USD 3) 50% deposit, 50% balance by T/T before shipment when order amount from 3000USD to 5000USD. 4) 30% deposit, 70% balance by T/T before shipment when order amount over 5000USD. 5) L/C payment term for big amount order is acceptable. |

| Trade terms | EXW, FOB, CIF, As per customer’s request |

| Shipment Terms | 1) 0-100kg: express & air freight priority 2) >100kg: sea freight priority 3) As per customized specifications |

| Note |

All CNC machining parts are custom made according to customer’s drawings or samples, no stock.If you have any CNC machining parts to be made, please feel free to send your kind drawings/samples to us anytime by email. |

KGL Machinery&Electronics Co., Ltd.(KGL) was founded in 2013, an independent private enterprise that integrated R&D, production, sales and service.KGL is focused on CNC precision machining parts, mainly applied in the field of robotics, communications, medical, automation, and custom-designed complex parts and custom-designed equipment.The core competitiveness is rapid response capability, quality assurance system and cost control ability.We provide value-added services to customers through more technical supporting, high quality product and rapid response business processing.So customers will be more focused on their own business and thus enhance customer value.

KGL Machinery&Electronics Co., Ltd.Now has high precision 3 axis CNC vertical machining center, 4 axis machining center, 5 axis machining center imported from ZheJiang , precision grinding machine, precision wire-cut, EDM and CNC lathe about 50 units.The Max machining range is 2100*1600*800mm, and the machining accuracy can be achieved to 0.005mm.The inspection instrument has CMM, profile projector, digital micro dial, high gauge, ID &OD micrometer, and so on.Professional and experienced management, engineers, inspectors and production staff is about 80.The main processing materials include cast iron, extruded material, steel, aluminum alloy, copper, stainless steel and various engineering plastics.

Our company is aiming at “professional quality and CZPT service”.We have passed ISO9001:2015 and ISO13485:2016 quality management system certification.The company has always been oriented by customer demand and respect for talents, constantly improve their strength, improve service level and quality.With many European and American, Asian and domestic customers, we have established long-term good relationship with common progress.Sincerely expect to join hands with you to create the future.

ISO13485:2003 ISO9001:2008

Exhibition:

Q1:Are you a manufacturer?

A1:Yes, we are a medium size ISO13485/ISO9001 certificated manufacturer with a wide range of advanced equipment.Warmly welcome to visit our factory so that you can make sure this point.

Q2:What is the MOQ?

A2:Minimum Order Quantity is 1 piece/set.If you require more qty,the price can be more competitive.

Q3:Can you do the mass production?

A3:Yes,we are a factory which can provide service of precision CNC machining, rapid prototyping, wire cutting, tooling building and etc.After you confirm the samples, we can start mass production.It is very convienient for customers to

Choose us as a one-stop solution supplier.

Q4:Which 3D drawing files should go with the machines?

A4:CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, for *STL format,it goes with 3D printer and SLA.

Q5:Is it possible to know how are my products going on without visiting your company?

A5:We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.

Q6:Will my drawings be safe after sending to you?

A6:Yes, we will keep them well and not release to third party without your permission.

Q7:What shall we do if we do not have drawings?

A7:Please send your sample to our factory,then we can copy or provide you better solutions.Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Thank you very much for reading, and warmly welcome to inquiry or visit us.

If any question please feel free to contact.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Central Spindle |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Stepped Shaft |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the torque specifications for securing an axle spindle to the suspension components?

The torque specifications for securing an axle spindle to the suspension components can vary depending on the specific vehicle make, model, and year. It’s important to refer to the manufacturer’s documentation or service manual for the accurate torque specifications. Here is a detailed explanation:

When installing or reassembling an axle spindle, it’s crucial to tighten the fasteners to the recommended torque specifications. This ensures proper clamping force and prevents issues such as overtightening, undertightening, or uneven loading. The torque specifications typically include values for the spindle nut, caliper bolts, and other related fasteners.

Since torque specifications can differ among vehicle models and years, it’s best to consult the appropriate manufacturer’s documentation or service manual for the exact torque values. These resources provide detailed information specific to your vehicle, ensuring accurate and safe installation. The documentation may be available in print form from the vehicle manufacturer, or in digital form through online service portals or third-party publications.

When referring to torque specifications, it’s essential to consider the following factors:

- Torque Units: Torque specifications are typically provided in either foot-pounds (ft-lbs) or Newton-meters (Nm). Ensure that you are using the correct unit of measurement to avoid errors.

- Torque Sequence: In some cases, the manufacturer may specify a specific sequence for tightening the fasteners. This sequence ensures even distribution of clamping force and proper alignment of components. Refer to the manufacturer’s documentation for any specified torque sequences.

- Thread Lubrication: Depending on the specific application, the manufacturer may recommend the use of a specific lubricant or thread-locking compound on the fasteners. Follow the manufacturer’s recommendations regarding lubrication to achieve accurate torque values.

- Re-Torqueing: In certain cases, the manufacturer may recommend re-torquing the fasteners after a specific mileage or driving time. This is done to account for any settling or relaxation that may occur in the components. Check the manufacturer’s documentation for any re-torqueing instructions.

It’s worth emphasizing that using the correct torque specifications is crucial to ensure the integrity and safety of the axle spindle and related components. Incorrectly tightened fasteners can lead to issues such as wheel bearing damage, premature wear, or even component failure.

If you are unsure about the torque specifications or lack the necessary tools and expertise, it is recommended to have a qualified mechanic or technician perform the installation or reassembly. They have the knowledge and experience to ensure that the axle spindle is secured with the appropriate torque, following the manufacturer’s specifications.

In summary, the torque specifications for securing an axle spindle to the suspension components vary depending on the vehicle make, model, and year. It is essential to consult the manufacturer’s documentation or service manual for the accurate torque values, taking into account torque units, torque sequence, thread lubrication, and any re-torqueing instructions. When in doubt, seek professional assistance to ensure proper installation and safe operation of the axle spindle.

How often should axle spindles be inspected as part of routine vehicle maintenance?

Inspecting axle spindles as part of routine vehicle maintenance is crucial for ensuring their continued performance, safety, and longevity. The frequency of axle spindle inspections can vary depending on several factors, including the vehicle type, driving conditions, and manufacturer recommendations. Here are some general guidelines:

- Manufacturer Recommendations: Refer to the vehicle’s owner’s manual or the manufacturer’s maintenance schedule for specific guidelines on axle spindle inspections. Manufacturers often provide recommended inspection intervals based on mileage or time, such as every 30,000 miles or every 2 years. Following the manufacturer’s recommendations ensures that you adhere to their specified maintenance intervals.

- Driving Conditions: Consider the driving conditions in which your vehicle operates. If you frequently drive in severe conditions such as off-road, dusty, or high-temperature environments, the axle spindles may require more frequent inspections. These conditions can contribute to accelerated wear or potential damage to the spindles, making more frequent inspections necessary to detect any issues early on.

- Visual Inspections: Perform visual inspections of the axle spindles regularly, especially during routine tire maintenance or brake inspections. Look for signs of damage, such as cracks, corrosion, or bent spindles. Pay attention to any unusual noise, vibration, or steering irregularities, as they can indicate potential issues with the spindles. If any abnormalities are observed, a more thorough inspection or professional evaluation should be conducted.

- Service Intervals: Take advantage of regular service intervals, such as oil changes or tire rotations, to have a qualified mechanic inspect the axle spindles. They can assess the condition of the spindles, check for proper lubrication, and identify any signs of wear or damage. The mechanic can recommend specific inspection intervals based on their expertise and the vehicle’s condition.

- Preventive Maintenance: In addition to regular inspections, consider incorporating preventive maintenance practices for your vehicle. This can include proactive measures such as applying protective coatings to the spindles, ensuring proper wheel alignment, and maintaining appropriate tire pressures. These actions can contribute to the longevity and optimal performance of the axle spindles.

It is important to note that the guidelines provided are general recommendations, and specific vehicle models or manufacturers may have different requirements. Therefore, always consult the vehicle’s owner’s manual or seek advice from a qualified mechanic or authorized dealership to determine the appropriate inspection frequency for the axle spindles in your vehicle.

Regular inspections of the axle spindles as part of routine vehicle maintenance help identify potential issues early, prevent further damage, and maintain the overall safety and reliability of the vehicle.

Are there differences between front and rear axle spindles in terms of design and function?

Yes, there are differences between front and rear axle spindles in terms of design and function. Here’s a detailed explanation:

The front and rear axle spindles serve similar purposes in a vehicle’s suspension system, but they have distinct characteristics and functions due to their positions and roles within the vehicle. Here are the key differences between front and rear axle spindles:

- Position: The front axle spindle is located at the front of the vehicle, usually connected to the steering system, while the rear axle spindle is positioned at the rear of the vehicle. The front spindle plays a crucial role in steering the vehicle, while the rear spindle primarily supports the rear wheel assembly.

- Steering Function: The front axle spindle is directly involved in the steering mechanism of the vehicle. It connects to the steering knuckle, which enables the front wheels to turn left or right, allowing the vehicle to change direction. The design of the front spindle incorporates features that facilitate steering, such as the attachment points for tie rods and steering components.

- Load Support: The rear axle spindle is primarily responsible for supporting the weight and load of the rear wheel assembly. It transfers the forces from the wheels to the suspension system and the vehicle chassis. The design of the rear spindle focuses on load-bearing capacity and durability to withstand the forces generated during acceleration, braking, and cornering.

- Drive Function: In vehicles with rear-wheel drive or four-wheel drive systems, the rear axle spindle may also have additional components for transmitting power from the drivetrain to the rear wheels. These components, such as axle shafts, differential gears, and drive flanges, are not typically found in front axle spindles.

- Braking System: Both front and rear axle spindles play a role in the vehicle’s braking system. However, the design and attachment points for brake components can vary between the front and rear spindles. The front spindle may incorporate mounting points for brake calipers and rotors, while the rear spindle may have provisions for brake drums or additional components for parking brake activation.

While there are differences in design and function between front and rear axle spindles, it’s important to note that these variations can also depend on the specific vehicle make, model, and suspension configuration. Different vehicles may have unique spindle designs and features tailored to their specific requirements.

Understanding the distinctions between front and rear axle spindles is important for proper maintenance, repair, and replacement. If you encounter issues with an axle spindle, it’s recommended to consult the vehicle’s manufacturer guidelines or seek assistance from a qualified mechanic or technician who can provide accurate diagnosis and appropriate solutions based on the specific axle spindle in question.

In summary, front and rear axle spindles differ in terms of position, steering function, load support, drive function (in certain cases), and braking system requirements. These differences arise from their respective roles in the vehicle’s suspension and drivetrain systems.

editor by CX 2024-02-09

China Custom Truck Spare Parts Spline Shaft OEM: 42311-35140 Used for CZPT Truck Superior Quality Rear Axle Drive Shaft with high quality

Product Description

Product Description

42311-35140 Rear axle half axle Rear wheel axle shaft for CZPT HILUX 4 1983-1988/HILUX 5 1988-1997

Because there are too many models, the table can’t show them all. Please consult online customer service.Thank you

|

NO. |

Oem |

Modle | Length/mm | Splines | Holes |

| 1 | 42311-263-01 | patriot Jeep | 874 | 10 | 10+2 |

| 26 | 42311-36210 | COASTER | 770/776 | 34 | 6+2+2 |

| 27 | 42311-37140 | Hino 300 | 865 | 37 | 10 |

Company Profile

FAQ

Q:Can you do OEM and provide samples firstly?

A:Yes,OEM and ODM are welcomed ,and with stocks ,samples can be shipped with 3 HangZhou as you need.

Q:What is the MOQ?payment term? and delivery time

A:For regular products, MOQ: 100PCS each model;

Once we get payment, we will ship your order within 20 working days.

The normal delivery time is 20days, depending on which country you are in.

Q:Where are you? Can we visit your factory?

A:Our factory is located in HangZhou, ZheJiang , China.

lt is close to HangZhou Airport, and the traffic at the west exit of HangZhou Sanquan Expressway is very convenient.

All employees of the company sincerely welcome domestic and foreign merchants to visit our company for guidance and business negotiation.

| After-sales Service: | 1year |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the key differences between live axles and dead axles in vehicle design?

In vehicle design, live axles and dead axles are two different types of axle configurations with distinct characteristics and functions. Here’s a detailed explanation of the key differences between live axles and dead axles:

Live Axles:

A live axle, also known as a solid axle or beam axle, is a type of axle where the wheels on both ends of the axle are connected and rotate together as a single unit. Here are the key features and characteristics of live axles:

- Connected Wheel Movement: In a live axle configuration, the wheels on both ends of the axle are linked together, meaning that any movement or forces applied to one wheel will directly affect the other wheel. This connection provides equal power distribution and torque to both wheels, making it suitable for off-road and heavy-duty applications where maximum traction is required.

- Simple Design: Live axles have a relatively simple design, consisting of a solid beam that connects the wheels. This simplicity makes them durable and capable of withstanding heavy loads and rough terrains.

- Weight and Cost: Live axles tend to be heavier and bulkier compared to other axle configurations, which can impact the overall weight and fuel efficiency of the vehicle. Additionally, the manufacturing and maintenance costs of live axles can be lower due to their simpler design.

- Suspension: In most cases, live axles are used in conjunction with leaf spring or coil spring suspensions. The axle is typically mounted to the vehicle’s chassis using leaf springs or control arms, allowing the axle to move vertically to absorb bumps and provide a smoother ride.

- Off-road Capability: Live axles are commonly used in off-road vehicles, trucks, and heavy-duty applications due to their robustness, durability, and ability to deliver power to both wheels simultaneously, enhancing traction and off-road performance.

Dead Axles:

A dead axle, also known as a dummy axle or non-driven axle, is a type of axle that does not transmit power to the wheels. It is primarily used to provide support and stability to the vehicle. Here are the key features and characteristics of dead axles:

- Independent Wheel Movement: In a dead axle configuration, each wheel operates independently, meaning that the movement or forces applied to one wheel will not affect the other wheel. Each wheel is responsible for its own power delivery and traction.

- Weight Distribution: Dead axles are often used to distribute the weight of the vehicle more evenly, especially in cases where heavy loads need to be carried. By adding an extra axle without driving capability, the weight can be distributed over a larger area, reducing the load on other axles and improving stability.

- Steering: Dead axles are commonly used as front axles in vehicles with rear-wheel drive configurations. They provide support for the front wheels and allow for steering control. The steering is typically achieved through a separate mechanism, such as a steering linkage or a steering gear.

- Reduced Complexity: Dead axles are simpler in design compared to live axles since they do not have the additional components required for power transmission. This simplicity can lead to lower manufacturing and maintenance costs.

- Efficiency and Maneuverability: Dead axles are often used in vehicles where power delivery to all wheels is not necessary, such as trailers, certain types of buses, and some light-duty vehicles. By eliminating the power transmission components, these vehicles can achieve better fuel efficiency and improved maneuverability.

It’s important to note that the choice between live axles and dead axles depends on the specific application, vehicle type, and desired performance characteristics. Vehicle manufacturers consider factors such as load capacity, traction requirements, off-road capability, cost, and fuel efficiency when determining the appropriate axle configuration for a particular vehicle model.

Where can I purchase high-quality replacement axles for my make and model of vehicle?

When it comes to purchasing high-quality replacement axles for your specific make and model of vehicle, there are several reliable sources you can consider. Here are some options:

- Authorized Dealerships:

- Independent Auto Parts Stores:

- Online Retailers:

- Specialty Performance Retailers:

- Local Salvage Yards:

- Vehicle Manufacturer’s Online Parts Store:

Authorized dealerships of your vehicle’s manufacturer are a trustworthy option for purchasing replacement axles. They offer genuine parts that are specifically designed and engineered for your make and model. Contact your local dealership’s parts department to inquire about the availability of replacement axles.

Independent auto parts stores often carry a wide range of replacement axles from reputable manufacturers. These stores typically have knowledgeable staff who can help you identify the correct axle for your vehicle. Examples of popular auto parts stores include AutoZone, Advance Auto Parts, and O’Reilly Auto Parts.

Online retailers provide a convenient way to browse and purchase replacement axles from the comfort of your home. Websites such as Amazon, eBay, and RockAuto offer extensive selections of axles for various vehicle makes and models. Be sure to verify the compatibility of the axles with your specific vehicle before making a purchase.

If you are looking for high-performance or upgraded axles, specialty performance retailers may be the way to go. These retailers cater to enthusiasts and offer axles that are designed to handle increased power, torque, or off-road demands. Examples of specialty performance retailers include Summit Racing, Jegs, and 4 Wheel Parts.

Salvage yards, also known as junkyards or auto recyclers, can be a cost-effective option for finding used axles in good condition. Some salvage yards have an inventory system that allows you to search for specific parts based on your vehicle’s make and model. It’s important to thoroughly inspect used axles before purchase to ensure they meet your requirements.

Many vehicle manufacturers have their own online parts stores where you can directly purchase genuine replacement parts, including axles. These online stores provide the assurance of authenticity and compatibility with your specific make and model. Visit the official website of your vehicle’s manufacturer and look for their parts store section.

When purchasing replacement axles, it’s important to prioritize quality and ensure that the parts meet or exceed the original equipment specifications. Consider factors such as warranty coverage, customer reviews, and the reputation of the manufacturer or retailer. Additionally, consult with knowledgeable professionals or refer to your vehicle’s owner’s manual for specific axle specifications and recommendations.

Can you explain the importance of axle alignment for vehicle stability and handling?

Axle alignment plays a crucial role in ensuring vehicle stability and handling characteristics. Proper alignment of the axles is essential for maintaining optimal tire contact with the road surface, minimizing tire wear, maximizing traction, and promoting safe and predictable handling. Here are the key reasons why axle alignment is important:

- Tire Wear and Longevity:

- Optimal Traction:

- Steering Response and Stability:

- Reduced Rolling Resistance:

- Vehicle Safety:

Correct axle alignment helps distribute the vehicle’s weight evenly across all four tires. When the axles are properly aligned, the tires wear evenly, reducing the risk of premature tire wear and extending their lifespan. Misaligned axles can cause uneven tire wear patterns, such as excessive wear on the inner or outer edges of the tires, leading to the need for premature tire replacement.

Proper axle alignment ensures that the tires maintain optimal contact with the road surface. When the axles are aligned correctly, the tires can evenly distribute the driving forces, maximizing traction and grip. This is particularly important during acceleration, braking, and cornering, as proper alignment helps prevent tire slippage and improves overall vehicle stability.

Axle alignment directly affects steering response and stability. When the axles are properly aligned, the vehicle responds predictably to driver inputs, providing precise and accurate steering control. Misaligned axles can lead to steering inconsistencies, such as pulling to one side or requiring constant correction, compromising vehicle stability and handling.

Proper axle alignment helps reduce rolling resistance, which is the force required to move the vehicle forward. When the axles are aligned correctly, the tires roll smoothly and effortlessly, minimizing energy loss due to friction. This can contribute to improved fuel efficiency and reduced operating costs.

Correct axle alignment is crucial for ensuring vehicle safety. Misaligned axles can affect the vehicle’s stability, especially during emergency maneuvers or sudden lane changes. Proper alignment helps maintain the intended handling characteristics of the vehicle, reducing the risk of loss of control and improving overall safety.

To achieve proper axle alignment, several key parameters are considered, including camber, toe, and caster angles. Camber refers to the vertical tilt of the wheel when viewed from the front, toe refers to the angle of the wheels in relation to each other when viewed from above, and caster refers to the angle of the steering axis in relation to vertical when viewed from the side. These alignment angles are adjusted to meet the vehicle manufacturer’s specifications and ensure optimal performance.

It’s important to note that factors such as road conditions, driving habits, and vehicle modifications can affect axle alignment over time. Regular maintenance and periodic alignment checks are recommended to ensure that the axles remain properly aligned, promoting vehicle stability, handling, and safety.

editor by CX 2023-12-11

China Truck Spare Parts OEM: 42311-0K030 Used for Toyota Truck Superior Quality Rear Axle Drive Shaft axle alignment

Product Description

Product Description

42311-0k030 Rear axle half axle Rear wheel axle shaft for Toyota

Because there are too many models, the table can’t show them all. Please consult online customer service.Thank you

|

NO. |

Oem |

Modle | Length/mm | Splines | Holes |

| 1 | 42311-263-01 | patriot Jeep | 874 | 10 | 10+2 |

| 26 | 42311-36210 | COASTER | 770/776 | 34 | 6+2+2 |

| 27 | 42311-37140 | Hino 300 | 865 | 37 | 10 |

Company Profile

FAQ

Q:Can you do OEM and provide samples firstly?

A:Yes,OEM and ODM are welcomed ,and with stocks ,samples can be shipped with 3 HangZhou as you need.

Q:What is the MOQ?payment term? and delivery time

A:For regular products, MOQ: 100PCS each model;

Once we get payment, we will ship your order within 20 working days.

The normal delivery time is 20days, depending on which country you are in.

Q:Where are you? Can we visit your factory?

A:Our factory is located in HangZhou, ZheJiang , China.

lt is close to HangZhou Airport, and the traffic at the west exit of HangZhou Sanquan Expressway is very convenient.

All employees of the company sincerely welcome domestic and foreign merchants to visit our company for guidance and business negotiation.

|

US $10-999 / Piece | |

100 Pieces (Min. Order) |

###

| After-sales Service: | 1year |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Application: | Truck |

| Certification: | ISO |

| Material: | 40cr Carbon Steel |

###

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

NO. |

Oem |

Modle | Length/mm | Splines | Holes |

| 1 | 42311-26300 | TOYOTA HAICE KDH211 RH | 825 |

30 |

6+1 |

| 2 | 42311-26290 | TOYOTA HAICE KDH20# RH | 733 | 30 | 6+1 |

| 3 | 42311-26301 | TOYOTA HAICE 2005 Narrow 1695 DIESEL | 825 | 30 | 6+1 |

| 4 | 42311-0K040 | TOYOTA HILUX 7 Vigo 2005-2015 KUN26 | 764 | 30 | 6+1 |

| 5 | 42311-0K030 | TOYOTA HILUX KUN25 RH | 764 | 30 | 6+1 |

| 6 | 42311-0K070 | TOYOTA HILUX KUN16 RH/HILUX DLX 5LE 2005-2013 | 764 | 30 | 5+1 |

| 7 | 42311-0K090 | TOYOTA HILUX KUN26 LHD RH | 764 | 30 | 6+1 |

| 8 | 42311-35330 | TOYOTA HILUX/4RUNNER TRUCK | 663 | 30 | 6+1 |

| 9 | 42311-35140 | TOYOTA HILUX 4 1983-1988/HILUX 5 1988-1997 | 663 | 30 | 6+1 |

| 10 | 42311-KK040 | 770 | 32 | 6+2 | |

| 11 | 42311-60240 | TOYOTA Landcruiser | 783 | 30 | 6+2 |

| 12 | 42311-60242 | TOYOTA Landcruiser | 783 | 30 | 6+2 |

| 13 | 42312-60070 | TOYOTA Landcruiser | 824 | 30 | 6+1 |

| 14 | 3W1Z-4234-A | Ford | 860 | 28 | 5 |

| 15 | 6W1Z-4234-A | Ford | 860 | 31 | 5 |

| 16 | F8AZ-4234-A | Ford | 809 | 28 | 5 |

| 17 | 42311-14990 | 990 | 39 | 10 | |

|

18 |

MB308901 | MITSUBISHI | 770 | 18 | 8+2 |

| 19 | MB308903 | MITSUBISHI | 800 | 18 | 8+2 |

| 20 | MC881679 | MITSUBISHI | 950 | 20 | 8 |

| 21 | MK499638/MC864169 | MITSUBISHI/Canter lntercooler FE74/75,Colt Diesel FE349/120PS | 802/805 | 18 | 8+2 |

| 22 | MK499638-M/MC864169-M | MITSUBISHI/Canter lntercooler FE74/75,Colt Diesel FE349/120PS | 805 | 18 | 8+2 |

| 23 | ME508085 | Canter lntercooler FE75 SHDX/H-Gear | 805 | 18 | 8+2 |

| 24 | 42311-0W030 /42311-LAA30 | TOYOTA | 774.5 | 37 | 8+2+2 |

| 25 | 3162-2403070-01 | patriot Jeep | 874 | 10 | 10+2 |

| 26 | 42311-36210 | COASTER | 770/776 | 34 | 6+2+2 |

| 27 | 42311-37140 | Hino 300 | 865 | 37 | 10 |

|

US $10-999 / Piece | |

100 Pieces (Min. Order) |

###

| After-sales Service: | 1year |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Application: | Truck |

| Certification: | ISO |

| Material: | 40cr Carbon Steel |

###

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

NO. |

Oem |

Modle | Length/mm | Splines | Holes |

| 1 | 42311-26300 | TOYOTA HAICE KDH211 RH | 825 |

30 |

6+1 |

| 2 | 42311-26290 | TOYOTA HAICE KDH20# RH | 733 | 30 | 6+1 |

| 3 | 42311-26301 | TOYOTA HAICE 2005 Narrow 1695 DIESEL | 825 | 30 | 6+1 |

| 4 | 42311-0K040 | TOYOTA HILUX 7 Vigo 2005-2015 KUN26 | 764 | 30 | 6+1 |

| 5 | 42311-0K030 | TOYOTA HILUX KUN25 RH | 764 | 30 | 6+1 |

| 6 | 42311-0K070 | TOYOTA HILUX KUN16 RH/HILUX DLX 5LE 2005-2013 | 764 | 30 | 5+1 |

| 7 | 42311-0K090 | TOYOTA HILUX KUN26 LHD RH | 764 | 30 | 6+1 |

| 8 | 42311-35330 | TOYOTA HILUX/4RUNNER TRUCK | 663 | 30 | 6+1 |

| 9 | 42311-35140 | TOYOTA HILUX 4 1983-1988/HILUX 5 1988-1997 | 663 | 30 | 6+1 |

| 10 | 42311-KK040 | 770 | 32 | 6+2 | |

| 11 | 42311-60240 | TOYOTA Landcruiser | 783 | 30 | 6+2 |

| 12 | 42311-60242 | TOYOTA Landcruiser | 783 | 30 | 6+2 |

| 13 | 42312-60070 | TOYOTA Landcruiser | 824 | 30 | 6+1 |

| 14 | 3W1Z-4234-A | Ford | 860 | 28 | 5 |

| 15 | 6W1Z-4234-A | Ford | 860 | 31 | 5 |

| 16 | F8AZ-4234-A | Ford | 809 | 28 | 5 |

| 17 | 42311-14990 | 990 | 39 | 10 | |

|

18 |

MB308901 | MITSUBISHI | 770 | 18 | 8+2 |

| 19 | MB308903 | MITSUBISHI | 800 | 18 | 8+2 |

| 20 | MC881679 | MITSUBISHI | 950 | 20 | 8 |

| 21 | MK499638/MC864169 | MITSUBISHI/Canter lntercooler FE74/75,Colt Diesel FE349/120PS | 802/805 | 18 | 8+2 |

| 22 | MK499638-M/MC864169-M | MITSUBISHI/Canter lntercooler FE74/75,Colt Diesel FE349/120PS | 805 | 18 | 8+2 |

| 23 | ME508085 | Canter lntercooler FE75 SHDX/H-Gear | 805 | 18 | 8+2 |

| 24 | 42311-0W030 /42311-LAA30 | TOYOTA | 774.5 | 37 | 8+2+2 |

| 25 | 3162-2403070-01 | patriot Jeep | 874 | 10 | 10+2 |

| 26 | 42311-36210 | COASTER | 770/776 | 34 | 6+2+2 |

| 27 | 42311-37140 | Hino 300 | 865 | 37 | 10 |

The Different Types of Axles

An axle is the central shaft of a gear or wheel. Axles are either fixed to the wheels or fixed to the vehicle. In some cases, they rotate together with the wheels and vehicle. The axle may also include bearings and mounting points. There are many types of axles, and it is important to understand the difference between each type.

Transaxle

The transaxle is the single mechanical device that combines the functions of a car’s differential, axle and transmission. It’s produced in manual and automatic models. A manual version is the preferred one for everyday driving, while an automatic one is more efficient in preventing vehicle damage. Here are some basics about the transaxle.

Transaxles are essential components of a car’s drivetrain, and any problems can cause major damage and leave the driver stranded. Transaxles include the transmission and the differential, which transfer the engine’s power to the wheels. Taking the time to check the transaxle is important to ensure that everything is functioning properly.

The transaxle is a very complex machine that combines the functions of the final drive and the transmission into one compact unit. The transaxle is a very versatile piece of automotive technology, and is an essential component of a front-wheel-drive car. In addition to conventional front-wheel-drive vehicles, many modern rear-wheel-drive vehicles use a transaxle to provide more even weight distribution.

The first American car to use a transaxle was the Cord 810 in the early 1920s. It was well ahead of its time, but was unsuccessful. For many years, the front-wheel drive automobile was absent from the United States automotive scene. It wasn’t until the 1960s that a front-wheel drive automobile re-emerged. A front-wheel-drive automobile, known as a transaxle, was the first to reach the market, and it’s not the only car to use this gearing.

A transaxle is a good option for vehicles with an extreme amount of torque. This system can handle powerful engine designs while keeping weight in the engine bay. It is not a perfect solution for all vehicles, however. In some vehicles, the extra weight added to the engine bay will affect the performance. The added weight will reduce traction. In addition, a transaxle mounts behind the engine, which adds weight to the rear.

Transaxles are the primary part of vehicles that have front-wheel drive. Their purpose is to transmit power from the engine to the drive wheels. The front-wheel-drive assembly had 2 short axles with complicated ball joints.

Full-floating axle

A full-floating axle is different from a semi-floating axle in several ways. A semi-floating axle is used for rear wheel drive cars, where it has a bearing mounted in the axle shaft. This axle supports the vehicle’s weight and transmits the drive torque from the transmission to the wheels. However, a semi-floating axle’s load capacity is limited by the size of the axle bearing. A full-floating axle, on the other hand, has the bearing mounted on the outside of the axle tube. The bearing is the only part of the axle that supports the vehicle, and the hub and bearing assembly are held together by a large nut.

The drive axle on a full-floating axle is splined at both ends so that it can easily be removed from the rear of a vehicle without removing the wheel. This type of axle makes it possible to change gears quickly and easily. Because of this, it’s not necessary to remove the wheels and tires in order to replace the axle. Instead, a common tool used to remove the axle from the wheel hub is an axle wrench.

Full-floating axles are more common in heavy-duty vehicles. The ability to carry heavy loads without causing the axle to break is a big advantage to full-floating axles. These axles require less maintenance and require less bends than traditional axles and may even be worth the extra investment if you have a heavy load to carry.

A full-floating axle allows the driver to change a broken axle shaft without having to remove the entire wheel. A full-floating axle will also allow the driver to remove the axle shaft without having to take off the wheel. Full-floating axles are also more durable than semi-floaters, which have weight resting on the axle tubes and housing.

While a full-floating axle is more expensive to manufacture, it is better for heavier vehicles that carry heavy loads. It is better to choose a full-floating axle if you have a heavy load or plan on towing.

Three-quarter floater

A three-quarter floating axle is a type of floating axle that’s a compromise between the full and semi-floating types. Its bearings are located on the axle casing rather than on the hub, which means that it’s less susceptible to axle breakdown. However, it’s not as robust as a full floating axle.

This design combines the benefits of fully-floating axles with the simplicity of a semi-floating axle. Instead of having multiple wheel bearings, a single wheel bearing is installed in the center of the hub. The hub is then keyed rigidly to the axle shaft, providing a connecting connection and maintaining wheel alignment.

While a full-floating axle is the most common style of truck axle, you may see the three-quarter floater on the side of a pickup. It was common for 3/4-ton Gms to use these axles until the 1980s. Dodge and Ford also used a semi-float axle called a Dana 60. The difference between the two types of axles is the amount of support provided by the axleshaft and hub, and the number of lug nuts on the axleshaft and hub are different.

The three-quarter floater axle drive assembly of the present invention is illustrated in FIG. 1. The axle housing comprises an elongated axle tube 12, a hub member 30, and a hub shaft 16. A hub member 30 is rotatably supported on the axle tube 12 by an anti-friction bearing assembly 42. The axle shaft is retained in place by a domed plate 26.

This axle design has two main advantages. First, it transfers the weight of the vehicle to the axle casing. It also helps transfer the driving torque and side thrust to the wheel. This type of axle also has a differential cross shaft, which limits inward axial movement of the axle shaft.

Dead axle

A Dead axle is a structural component that supports the rear wheel of a vehicle. It can either be straight or angled and is located behind the drive axle. Depending on the vehicle, the dead axle may be steerable. Tag axles are also common on agricultural equipment and certain heavy construction machinery. They are also known as lazy axles because they only contact the ground when a vehicle is carrying a significant load, thus saving tire wear. Dead axles may be rigid or flexible.

Some rear dead axles can also be configured as an air tank. The air is taken in and out of the rear dead axle through the port portions of the rear axle. This can reduce the size of the air tank. For this reason, it is a preferred design for rear dead axles. While most vehicles are equipped with two axles, the rear axle can be used to accommodate cargo.

FIG. 1 is a schematic plan view of a vehicle with two rear axles. The front axle is called the drive axle and the rear dead axle is called the dead axle. These components are located on a truck body frame. There are also battery and fuel tanks. They are used to distribute driving force from the front to rear wheels.

An axle is a crucial component of a vehicle. It transfers power from the engine to the wheels. A live axle is connected to the drive shaft and transmission, while a dead axle receives no direct power. This is the main difference between a live and dead axle. Although a dead axle is not as useful as a live one, it is still essential to understand what drives a car.

Dead axles are used in many vehicles for different purposes. Many large trucks are fitted with several of them for load bearing purposes. They also help distribute weight.

editor by czh

China factory High Quality 250W 24V Electric Gof Cart Rear Axle Shaft Drive for Electric Vehicle with Good quality

Warranty: 3months-1year

Product Quantity: LD01

Use: BOAT, Auto, Electric Bicycle, Enthusiast, Home Equipment, Beauty instrument

Sort: Equipment MOTOR

Torque: 14N.m

Building: Long lasting Magnet

Commutation: Brush

Protect Attribute: Completely Enclosed

Pace(RPM): 160RPM

Ongoing Current(A): 15A

Performance: IE 2

Item Identify: Brush dc motor

Rated Energy: 250W

Rated Voltage: 24V

Rated Pace: 160RPM

Rated Current: 15A

Motor variety: Dc Brush Gear Motor

Brush Variety: Metallic Carbon Brush

Software: Electric Car Automobile

Employing Temperature: -10℃~+40℃(Nonfreezing)

Utilizing Humidity: ≤85%(Area with no dew)

Certification: ce

Packaging Particulars: carton

Item Overview Substantial Top quality 250W 24V Electric powered Gof Cart Rear Axle Shaft Travel for Electrical Vehicle Drive AxleDrive MotorModelNo-load SpeedRated SpeedRated TorqueRated VoltageRated PowerRated CurrentRated TorqueRated SpeedNo-load Speedr/minr/minN.mVWAN.mr/minr/minLD01-25571517013.22425016.fifty.7930184171 Solution Parameters Electrical push axle motorone. The 24v volt DC motor drives the tiny electric powered vehicle motor differential assembly and the differential rear axle. two. A specialist design and style to achieve decrease noise3. Substantial good quality resources, exact processing and workmanship to make it durable top quality.4. Stream line form and frame types to make it a most rather product. Item Details Minimal Sounds, WATERPROOFwaterproof degree up to IP65 Inner SPUR Gear DIFFERENTIALmake steering smoother WITH ELECTROMAGNETIC BRAKE far more safe and dependable to use Lower Sound, Large EFFICIENCYself-produced, far more successful Apps This electrical generate axle dc motor has a broad range of apps. It is commonly utilised for go cart, mini robotic, sweeper, mainstream vacation trailer, Engineering cars, 300 Advance Marine Gearbox for Maritime Reverse Transmission Specific automobiles,m edical amenities, mobility scooter for old folks, cleaning devices, electrical wheelchairs, warehouse transport thrust cart, and so on. Scooter Kid Cart Mini Robotic Sweeper Why Select Us Our gain: Stringent generation process: Package deal&Shipping Outer packing: Regular export carton with required delivery marksInner packing: Waterproof packing with shock absorbing EPE and cardboard surroundedAs for every the clientele specificationsCargo: TNT, DHL, UPS, FedEx, By Sea are available. The other delivery approaches are also obtainable. Rigid merchandise packaging guarantees that the motors is not broken throughout transportation. Company Profile LUNYEE INDUSTRIES Growth CO, Restricted was established in 2007, is a major company for manufacturing facility automation (FA) merchandise! We are focused in electrical power transmission and movement handle options! Scorching Sale Automatic Gearbox CVT Transmission Elements Suit For Geely EC7 VT2 Gearbox Our ProductsWe manufacture electricity transmission merchandise like AC and DC(brush/brushless) equipment motor, high precision planetary gearbox (spur/helical gear) for servo motor and stepping motor, linear motion merchandise like linear bushing, linear information, ball screw, locking nut and coupling and so on! Our ServiceA satisfying a single-phase support arrives from our steady innovation group and our rigorously-inspected sub-contractors! Our items are commonly utilized to equipment instruments, industrial robotic, textile device, packing equipment, foodstuff device, health care device, CNC system and air issue and so on! FAQ Q: Are you trading organization or company?A: We are the motor maker for fifteen a long time in China. Q: How to purchase?A: deliver us inquiry → South The usa Sliding Doorway Roller Window Wheel Aluminum Alloy Window Roller Plastic Pulley Double Wheel rodamientos ventanas obtain our quotation → negotiate particulars → verify the sample → sign agreement/deposit → mass production → cargo ready → balance/supply → even more cooperation Q: How about Sample get?A: Sample is available for you. make sure you make contact with us for details. As soon as we demand you sample fee, you should really feel simple. It would be refound when you place formal order. Q: Which shipping way is accessible?A: DHL, FedEx, By Sea are available. The other shipping techniques are also available, make sure you get in touch with us if you want ship by the other transport way. Q: How extended is the deliver, creating and transport?A: Supply time relies upon on the quantity you order. normally it will take fifteen-25 operating times. Q: My package has lacking products. What can I do?A: Remember to speak to our support group and we will verify your buy with the package deal contents. We apologize for any inconveniences. Q: How to verify the payment?A: We take payment by T/T, PayPal, the other payment techniques also could be accepted, JF015E RE0F11A Transmission gearbox Overhaul package You should get in touch with us ahead of you pay out by the other payment techniques. Also thirty fifty% deposit is obtainable, the balance cash ought to be paid ahead of delivery.If you have one more issue, pls feel cost-free to make contact with us.

Guidebook to Push Shafts and U-Joints

If you happen to be anxious about the performance of your car’s driveshaft, you’re not on your own. Numerous vehicle house owners are unaware of the warning signs of a unsuccessful driveshaft, but knowing what to search for can aid you avoid high priced repairs. Here is a brief guidebook on generate shafts, U-joints and upkeep intervals. Detailed under are essential details to think about just before replacing a automobile driveshaft.

Signs of Driveshaft Failure

Identifying a faulty driveshaft is straightforward if you have ever heard a peculiar sound from under your auto. These sounds are caused by worn U-joints and bearings supporting the generate shaft. When they are unsuccessful, the drive shafts end rotating correctly, generating a clanking or squeaking seem. When this occurs, you might listen to sound from the side of the steering wheel or flooring.

In addition to sound, a defective driveshaft can result in your auto to swerve in restricted corners. It can also guide to suspended bindings that limit all round control. For that reason, you must have these symptoms checked by a mechanic as shortly as you observe them. If you notice any of the indicators earlier mentioned, your next stage must be to tow your automobile to a mechanic. To avoid further difficulties, make certain you’ve got taken precautions by examining your car’s oil level.

In addition to these signs, you need to also appear for any sounds from the generate shaft. The first thing to appear for is the squeak. This was induced by extreme hurt to the U-joint attached to the travel shaft. In addition to noise, you should also search for rust on the bearing cap seals. In severe circumstances, your car can even shudder when accelerating.

Vibration while driving can be an early warning signal of a driveshaft failure. Vibration can be thanks to worn bushings, trapped sliding yokes, or even springs or bent yokes. Excessive torque can be caused by a worn center bearing or a broken U-joint. The automobile may make unusual noises in the chassis program.

If you recognize these indicators, it truly is time to get your auto to a mechanic. You ought to verify routinely, specifically large autos. If you are not positive what’s creating the sounds, check your car’s transmission, engine, and rear differential. If you suspect that a driveshaft demands to be replaced, a qualified mechanic can exchange the driveshaft in your vehicle.

Travel shaft type

Driveshafts are employed in numerous diverse varieties of automobiles. These contain four-wheel drive, front-engine rear-wheel generate, motorcycles and boats. Each and every sort of travel shaft has its possess goal. Beneath is an overview of the three most widespread varieties of travel shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the motor to the wheels. Travel shafts often have numerous joints to compensate for alterations in length or angle. Some generate shafts also include connecting shafts and inner continuous velocity joints. Some also incorporate torsional dampers, spline joints, and even prismatic joints. The most crucial issue about the driveshaft is that it performs a vital position in transmitting torque from the motor to the wheels.

The push shaft wants to be each mild and robust to go torque. Whilst steel is the most generally used material for automotive driveshafts, other components these kinds of as aluminum, composites, and carbon fiber are also commonly employed. It all is dependent on the function and dimension of the automobile. Precision Manufacturing is a excellent supply for OEM items and OEM driveshafts. So when you happen to be hunting for a new driveshaft, keep these aspects in head when buying.

Cardan joints are an additional common drive shaft. A universal joint, also identified as a U-joint, is a versatile coupling that enables 1 shaft to push the other at an angle. This kind of travel shaft makes it possible for electrical power to be transmitted while the angle of the other shaft is continuously shifting. Whilst a gimbal is a excellent choice, it is not a excellent resolution for all applications.

CZPT, Inc. has state-of-the-artwork equipment to service all sorts of travel shafts, from modest autos to race automobiles. They serve a selection of demands, which includes racing, sector and agriculture. Regardless of whether you need to have a new drive shaft or a basic adjustment, the workers at CZPT can fulfill all your demands. You will be back again on the street before long!

U-joint

If your auto yoke or u-joint exhibits symptoms of put on, it’s time to exchange them. The easiest way to change them is to follow the actions under. Use a huge flathead screwdriver to check. If you come to feel any motion, the U-joint is faulty. Also, examine the bearing caps for hurt or rust. If you can not uncover the u-joint wrench, try examining with a flashlight.

When inspecting U-joints, make positive they are appropriately lubricated and lubricated. If the joint is dry or badly lubricated, it can quickly fail and lead to your vehicle to squeak although driving. Yet another signal that a joint is about to are unsuccessful is a sudden, extreme whine. Check your u-joints every 12 months or so to make positive they are in proper functioning get.

No matter whether your u-joint is sealed or lubricated will rely on the make and design of your motor vehicle. When your vehicle is off-road, you require to install lubricable U-joints for toughness and longevity. A new driveshaft or derailleur will expense much more than a U-joint. Also, if you will not have a excellent comprehension of how to replace them, you might need to do some transmission operate on your motor vehicle.

When changing the U-joint on the generate shaft, be sure to pick an OEM substitution anytime attainable. Even though you can effortlessly fix or substitute the first head, if the u-joint is not lubricated, you could want to change it. A destroyed gimbal joint can cause issues with your car’s transmission or other crucial elements. Changing your car’s U-joint early can make sure its extended-term functionality.